Problem Problem Of Fish Feed Equipment

Your floating fish feed maker will certainly appear several troubles after it functioned a long time, or because of your incorrect operation, your fish feed machine has taken place troubles or not working well even stopped working.

Usual troubles are low production output, expensive puffing or not enough puffing, and poor pellet developing, against these trouble problems, specifically on poor pellet forming issue, several of our customers satisfied this sort of issue, some because of basic materials formula, some because of incorrect operation, as well as in below we will certainly provide some troubleshooting and services for you.

Repairing Of Fish Feed Machine

Solutions Of Low Production Result

1. The screw head is put on greatly, please change the screw head or the entire screw

2. The bushing of the extrusion chamber is used greatly, please transform the bushing in the extrusion chamber

3. If you altered the formuation or otherwise? for sinking type pellets: starch web content percentage: ≥ 20%, for floating kind pellets: starch content portion: ≥ 10%. Additionally: Particularly for floating products, the material of pet protein ought to not be too high.

The role of starch:

1). Starch has solid water absorption;

2). The gelatinized starch can improve the viscosity of the product

3). Double feature of puffing as well as binding in the final pellets

The role of protein:

1). Protein has water absorption, flexibility and also coagulation

2). Healthy protein is divided right into: veggie protein as well as animal healthy protein, Solutions consisting of veggie protein are generally much easier to refine than those having pet healthy protein. Due to the fact that animal healthy protein is not as simple to incorporate with various other components or mass as vegetable healthy protein or starch

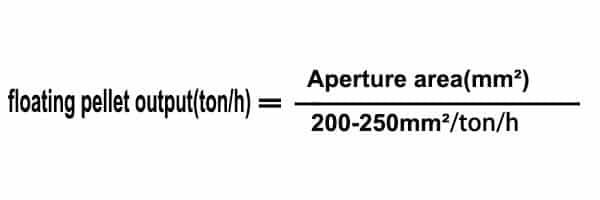

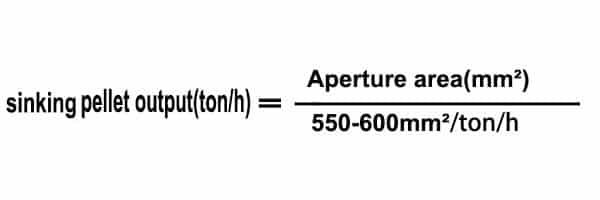

4. Is the aperture area of the die appropriates or otherwise?

A= 1aperture area area= πr2, 10holes-8mm die 8mm diameter= 4mm redius.

area= πr2, 3.14 × 16= 50.24 mm2.

10 holes × 50.24= 502.4 mm2.

Solutions Of Too Expensive Puffing Or Not Sufficient Puffing.

1. the raw materials are puffed much also highly.

1) the conditioner temperature is too expensive( for wet type maker).

2) the turning speed of the host machine is too high.

3) too much or also much less water added in the raw products or in the conditioner.

4) the holes of the die mould is blocked.

2. The puffing degree of the material is not nearly enough.

1) the extruder production ourput is reduced.

2) the conditioner temperature is insufficient high.

3) the turning speed of the host maker is too low.

4) the heating plate temperature level in the extrusion chamber is as well low.

5) water web content is also reduced in the conditioner or in the raw product.

6) have you ever transformed the solution.

3. Poor pellet forming.

1) the raw products formulation is not so great.

2) the functioning temperature is expensive or as well reduced.

3) feeding resources is not stabilized.

4) the cutting speed is not correct, expensive or too reduced.

5) the cutting blades are put on.

6) the size of powder resources is as well large, you can check here the raw products size requirement.

die mold aperture φ (mm) grinding fineness required.

1.0 95% reach to 90-100 mesh.

1.5 95% reach to 80 mesh.

2.0 95% reach to 80 mesh.

3.0 95% reach to 60 mesh.

4.0 95% reach to 60 mesh.

5.0 95% reach to 60 mesh.

4. The final pellets are harsh surface area as well as different sizes.

1) some partial holes of the die mould are obstructed.

2) the finness of the raw products is not nearly enough.

3) the raw products conditioning is not good.

4) the quality of the die mould holes is poor.

5) the reducing blades are worn.

6) the water portion in the raw materials is not fix.

5. The extrusion temperature level is as well reduced.

1) the steam conditioning temperature is also low (for damp kind equipment).

2) The steam inlet pipe of the puffing chamber is blocked or the temperature level of the electric home heating tool is inadequate( for wet kind machine).

3) Jacketed vapor line (catch) plugged( for damp kind maker).

4) The temperature of the electric home heating plate is as well low or the electric home heating button is not turned on.

5) Basic material wetness is expensive.

6. Fragments are obstructed before exiting the die hole.

1) The fragment dimension of the raw material is also large about the size of the die hole.

2) The amount of water is insufficient to make the product circulation.

3) the screw rod is used substantially.

4) The feeding inlet is blocked.