In order to reduce the feed cost and fish diseases in aquaculture farms, Richi Machinery has launched a floating fish feed making machine; the fish pellet feed produced by the fish feed pellet extruder can effectively prevent and control fish diseases.

1.Use of floating fish feed making machine

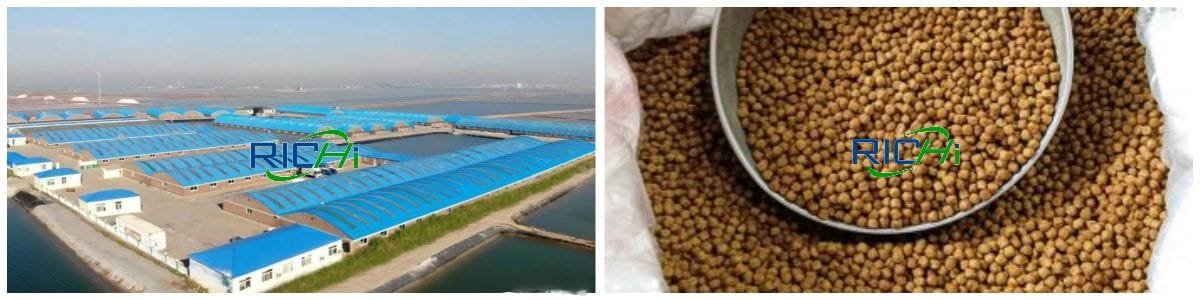

Fish feed pellet machine is widely used in large, medium and small aquaculture, grain feed processing plants, livestock farms, poultry farms, individual farmers and small and medium-sized farms, farmers or large, medium and small floating fish feed production line.

2.Precautions when using floating fish feed making machine

- When the fingerlings are stocked, when the water temperature is low, the growth is slow, and the size is small, the pellet diameter of the feed should be controlled at about 2mm; when the temperature rises and the growth of fingerlings is accelerated, the diameter of the feed pellets in the mid-term should be 3-3.5mm , and later in 4-4.5mm.Therefore, when using the floating fish feed making machine to process fish pellet feed, the size of the feed pellets should be adjusted according to different periods to achieve the best feeding effect.

- Because the fish has no stomach, the feed stays in the intestinal tract for a very short time, and the digestion and utilization rate is not high; therefore, when feeding the feed, it should be fed several times, and each feeding should be a little less feed utilization.

- Fish pellet feed contains 12% – 14% of water during the floating fish feed making machineproduction process, and it is not easy to store for too long, so as to avoid deliquescence, mildew, and disease after feeding the fingerlings, so it is best to produce and feed it at the same time.

- In order to better prevent the release of diseased fish fingerlings, adding 1% salt to the feed powder before production can effectively prevent the occurrence of diseases of fingerlings. (Related post: 4-5T/H Floating Fish Feed Plant)

3.Performance of floating fish feed making machine

- Scientific and reasonable structural design, simple, small footprint and low noise.

- Small floating fish feed making machine for dry in and dry out, easy to make materials, high output and low energy consumption.

- This floating fish feed making machine has a high pellet forming rate, and the resulting pellets have high hardness and smooth surface, which is convenient for storage and transportation.

- This model floating fish feed making machineis equipped with Ø1.5—- Ø20 kinds of aperture molds, which are suitable for granulation of different materials and achieve better results.

- Adapt to different materials to ensure the pressing effect.

- Simple operation and maintenance, safe and reliable

- Strong adaptability to the workplace

- The floating fish pellet machinebody is cast as a whole, the structure is firm and the appearance is beautiful, and the service life is long.

4.Advantages of RICHIfloating fish pellet machine

- Uniform discharge, smooth pellets, and output increased by 50%.

- The produced granules by floating fish feed making machine are formed at one time, with high hardness, smooth surface and sufficient internal ripening, which can improve the digestion and absorption of nutrients. Better for storage.

- The floating fish feed making machine has humanized design, small footprint, low noise, emergency button, simple and safer operation.

- RICHI floating fish food machine can be customized according to customer needs. (Related post: 6-7T/H Fish Feed Plant)

- RICHI floating fish feed making machine belongs to the factory direct sales, there is no middleman, the price is cheap, the profit is low, and it is all installed and debugged before delivery, and then packed and shipped.

- RICHI floating feed making machine is packed in plastic (plastic waterproof) before delivery.

- Before the final delivery, the floating fish feed pellet making machine is put on all-wood packaging, and the whole machine is packed in a wooden box to ensure that the floating pellet machine reaches the destination safely and without damage.

5.Process composition of floating fish feed extruder:

- Mixing machine: Add a certain proportion of water to the raw materials, such as corn flour, rice flour, soybean flour, fish meal, meat meal, grain flour, additives, etc., and mix them evenly.

- Feeder: Using the motor as the power for screw conveying, the mixed raw materials are transported to the feeding hopper of the floating fish feed extruder machine to ensure convenient and fast feeding.

- Twin-screw floating fish feed extruder: In the case of high temperature and high pressure environment and screw extrusion, the mold can be replaced by adjusting the process to produce different feeds, and the specific pelletsize and shape can be changed.

- Conveyor: to transport the feed to the oven.

- Multi-layer oven: Most of the ovens are electric ovens, the temperature is adjusted between 0-200 degrees through the control cabinet, and the interior is a stainless steel double-layer mesh bag, which reduces the moisture of feed pellets, promotes the curing rate, and increases the shelf life.

- Seasoning line: The oil sprayer sprays oil, food attractant, etc. The seasoning drum includes octagonal drum, cylinder, lifting single drum, and double drum seasoning line. According to the output and product properties, the oil is sprayed on the surface of the feed, and sprayed at the same time. Minced meat and spices, sprinkle evenly.

- Cooling and conveying: reduce the temperature of frying and feed, promote the solidification of oil, reduce the temperature of pellets, and facilitate packaging.

- Vibrating sieve: sieve off excess external material and pellets at the end of the year to ensure the quality and the reuse of raw materials.

- Packaging machine: manual sealing machine and automatic packaging machine can be used.

6.Questions about floating fish feed making machine

(1)Q: Which is the best small floating fish feed making machine?

Answer: At present, there are many manufacturers of small floating fish feed pellet machines, which are mixed. In order to avoid purchasing machines with poor quality, users should choose regular manufacturers to buy them.

A professional floating fish feed making machine manufacturer should have the following three points:

- A regular floating pellet machine manufacturer.

- Excellent machine quality,

- Perfect after-sales service.

(2)Q: Is the small floating fish feed making machine durable? how much is it?

Answer: You must be familiar with the small floating pellet machine. What is the effect of this machine? Is it easy to use? This floating fish feed making machine is a feed processing equipment specially designed for breeding poultry.

- The compound feed formula has a variety of raw materials. Nutritional balance.

- Reduce disease and improve survival rate.

- Save feed cost for breeders and improve economic benefits. The specific price requires the user to determine the model first, and then let the floating pellet machinemanufacturer quote.

(3)Q: How much is the price of the small floating feed extruder machine?

Answer: The decisive factor for the price of the small floating feed extruder machine lies in the output, raw materials and power. The higher the output, the higher the price of the corresponding floating fish feed making machine, and the greater the power, the higher the price.

Therefore, before purchasing, first decide how much output you want, and then let the floating fish feed making machine manufacturer give an accurate quotation.

(4)Q: How much is the small fish feed pellet machine?

A: The power of the small floating fish feed making machine is 2.2kw with two-phase electricity, and the hourly output of feed pellets is about 60-100 kilograms. The price of a high-quality machine with a motor is about 2000-200000USD.

(5)Q: What is floating feed machine price?

Answer: Thefloating fish feed pellet mill is a multi-functional feed pellet machine, which can be used to process animal feeds such as chickens, ducks, and geese, improve the survival rate. The price is 2000-200000USD.