The shrimp aquaculture industry has seen significant growth in recent years, leading to a heightened demand for high-quality shrimp feed. To meet this demand, shrimp feed manufacturers rely on specialized equipment, particularly shrimp feed pellet machines. These machines must fulfill specific requirements to ensure the production of optimal shrimp feed. This article delves into the key requirements for shrimp feed pellet machines in the context of shrimp feed processing.

High Moisture Handling Capability

One of the primary requirements for shrimp feed pellet machines is their ability to handle high moisture content in the feed mixture. Shrimp feed typically requires a moisture content of 15-18%, which is higher than that of many other animal feeds. The pellet machine must be designed to:

- Process feed mixtures with moisture content up to 18% without clogging or compromising pellet quality.

- Maintain consistent pellet formation despite high moisture levels.

- Prevent excessive wear on machine components due to increased moisture.

Precise Temperature Control

Temperature control is crucial in shrimp feed processing. The pellet machine should have:

- Adjustable temperature settings to achieve optimal starch gelatinization and protein denaturation.

- The ability to maintain consistent temperatures throughout the pelleting process.

- Temperature monitoring systems to prevent overheating, which can damage heat-sensitive nutrients.

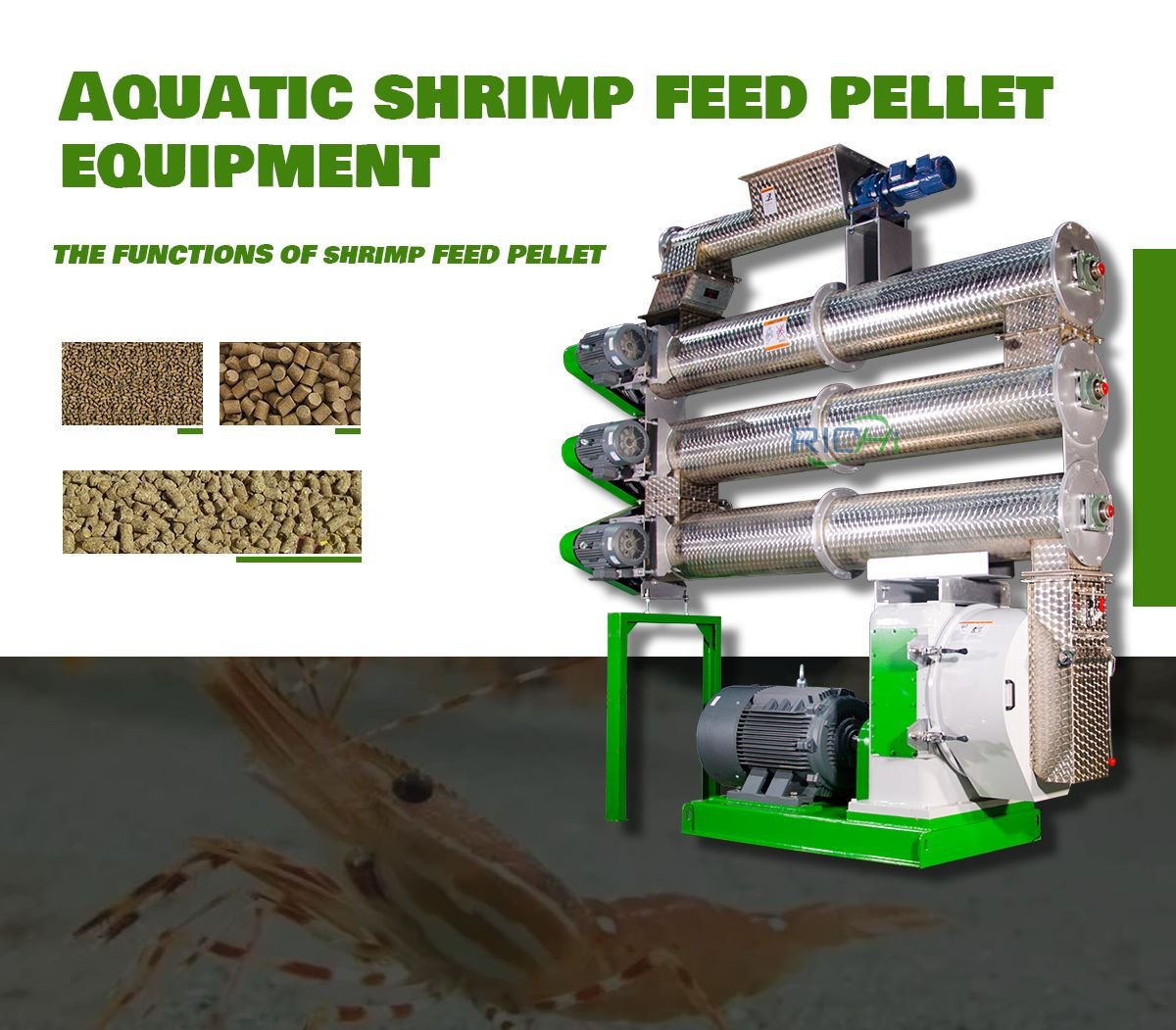

Advanced Conditioning System

A multi-layer conditioning system is essential for producing high-quality shrimp feed pellets. The machine should feature:

- Two or three-stage conditioning for thorough and uniform moisture distribution.

- Adjustable retention time in each conditioning stage.

- Steam injection capabilities for optimal ingredient hydration and cooking.

Pellet Size Versatility

Shrimp at different growth stages require different pellet sizes. The machine must offer:

- Adjustable die sizes to produce pellets ranging from 0.8mm to 3mm in diameter.

- Easy die change mechanisms for quick size adjustments.

- Consistent pellet size and shape across production runs.

High Water Stability of Produced Pellets

Since shrimp are slow feeders, the pellets must maintain integrity in water for extended periods. The feed pellet machine should:

- Produce pellets with excellent water stability (4-6 hours or more).

- Allow for the incorporation of binders and other ingredients that enhance water stability.

- Provide sufficient compression and shear forces to create dense, stable pellets.

Efficient Ingredient Mixing

Thorough mixing of ingredients is crucial for nutritional consistency. The pellet machine should include:

- Pre-mixing capabilities or integration with efficient mixing systems.

- Design features that promote uniform distribution of ingredients during the pelleting process.

- The ability to handle a wide range of ingredients, including plant-based proteins and marine ingredients.

High Production Capacity

To meet the growing demand for shrimp feed, the machine must offer:

- Scalable production capacity, typically ranging from 1 to 20 tons per hour.

- Consistent output quality even at high production rates.

- Energy-efficient operation to maintain cost-effectiveness at various production scales.

Durability and Corrosion Resistance

Given the high moisture content and potential use of corrosive ingredients, the machine must be:

- Constructed with corrosion-resistant materials, particularly stainless steel for parts in contact with feed.

- Built to withstand continuous operation in humid environments.

- Designed for easy cleaning and maintenance to prevent ingredient build-up and contamination.

Precision Control Systems

Modern shrimp feed pellet machines should incorporate advanced control systems:

- PLC (Programmable Logic Controller) systems for precise control of all processing parameters.

- Touch-screen interfaces for easy operation and monitoring.

- Real-time data logging and reporting capabilities for quality control and traceability.

Energy Efficiency

Energy consumption significantly impacts feed production costs. The machine should feature:

- Energy-efficient motors and drive systems.

- Optimized die and roller designs to reduce energy consumption during pelleting.

- Heat recovery systems to utilize waste heat and improve overall energy efficiency.

Flexibility in Feed Formulation

The machine must handle various feed formulations, including:

- Processing a wide range of ingredients, including alternative protein sources.

- Accommodating different fat levels in feed formulations.

- Allowing for the incorporation of additives and supplements at various stages of the pelleting process.

Hygiene and Safety Features

Maintaining feed hygiene and operator safety is paramount. The machine should include:

- Easy-to-clean surfaces and components to prevent bacterial growth.

- Safety interlocks and emergency stop mechanisms.

- Dust collection systems to maintain a clean working environment.

Integration Capabilities

The pellet machine should easily integrate with other equipment in the feed production line:

- Compatibility with automated feeding and packaging systems.

- The ability to synchronize with upstream and downstream processes.

- Data integration capabilities for overall production monitoring and control. (Related post: fish feed pellet making machine)

Customization Options

Given the diverse needs of shrimp feed producers, the machine should offer:

- Customizable features to meet specific production requirements.

- A modular design for easy upgrades or modifications.

- Options for additional components, such as post-pellet coating systems.

Compliance with Industry Standards

The machine must meet relevant industry standards and regulations, including:

- Compliance with food safety standards for feed production equipment.

- Adherence to energy efficiency and environmental regulations.

- Certification from relevant industry bodies or authorities.

After-Sales Support and Spare Parts Availability

Reliable after-sales support is crucial for maintaining continuous operation:

- Availability of technical support and maintenance services.

- Ready access to spare parts and wear components.

- Training programs for operators and maintenance staff.

Conclusion

The requirements for shrimp feed pellet machines in shrimp feed processing are multifaceted, reflecting the complex nature of shrimp nutrition and the demanding conditions of aquaculture feed production. A high-quality shrimp feed pellet machine must produce pellets with excellent physical characteristics and nutritional integrity while offering flexibility, efficiency, and reliability in operation.

As the shrimp aquaculture industry continues to evolve, these requirements are likely to become even more stringent. Feed manufacturers and equipment suppliers must collaborate closely to develop and refine pellet machines that can meet these demanding specifications. By investing in machines that fulfill these requirements, shrimp feed producers can ensure the production of high-quality feed, contributing to the efficiency and sustainability of shrimp aquaculture operations worldwide.